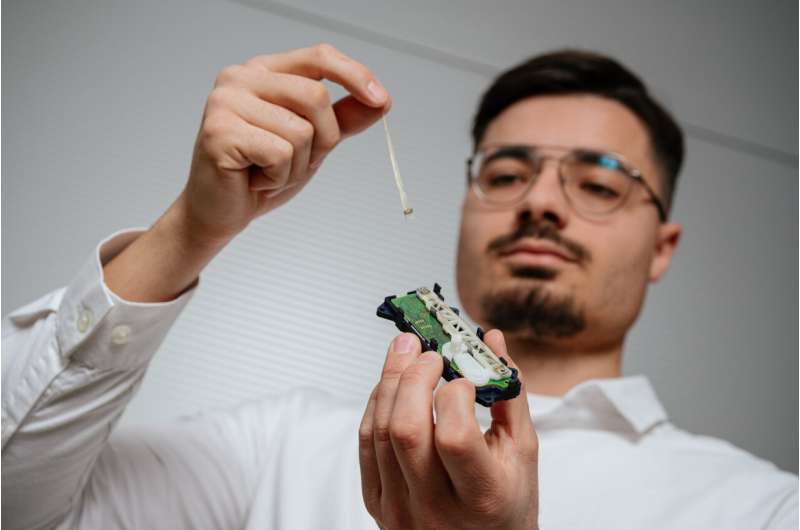

Researchers are using artificial muscles made from nickel-titanium alloy to build compact technical components. Doctoral student Carmelo Pirritano is currently researching these novel smart drive systems. Credit: Oliver Dietze

Wherever electric motors or electromagnets are too large or too heavy to be incorporated into a technical component, the novel drive mechanisms being developed by a research team led by Professors Stefan Seelecke and Paul Motzki at Saarland University can help to save space, weight and energy.

Their shape-memory drives have a diameter of 300–400 microns and are ultralight and very energy efficient. Using artificial muscles made from the alloy nickel-titanium, the team is able to make miniature drive components for use in highly confined, but also much larger spaces. The research team will be showcasing their technology at this year's Hannover Messe.

In today's world, ever more technology has to be fitted into ever smaller spaces. Space is at a premium inside cars, planes and other machines and devices. And overall weight is another important consideration. The lighter the vehicle, the less fuel it needs, or in the case of electric vehicles, the longer the battery will last. In future, a novel type of technology currently under development could help to make components smaller and lighter, and consume less energy.

A research team led by smart material specialists Stefan Seelecke and Paul Motzki, based at Saarland University and the Center for Mechatronics and Automation Technology (ZeMA) in Saarbrücken, is developing the novel components with the aim of having them manufactured commercially.

The Saarbrücken-based scientists are exploiting the properties of intelligent materials in order to provide drive components with artificial muscles. These components find use wherever something has to rotate or where switches have to be installed in tight spaces. In fact, they can deliver the sort of large-torque, large-angle rotational motion that currently requires the use of much larger motors, or hydraulic or pneumatic systems.

The prototype that the research team is showcasing at this year's Hannover Messe from 17 to 21 April (Hall 002, Stand B34) contains strands of artificial 'muscle' made from ultrathin nickel-titanium wires that can contract or relax depending on the applied current. The wires are able to exert a substantial tensile force over a very short distance. "These artificial muscles made from nickel-titanium alloy have the highest energy density of all known drive mechanisms," explained Professor Stefan Seelecke.

The ultrafine wires contract or relax like real muscle fibers, depending on whether an electric current is flowing or not. "Nickel-titanium alloy is what is known as a shape-memory material. At the level of the crystal lattice, the material can exist in two phases that can transform into each other. When the material is in one phase, it 'remembers' the lattice structure in the other phase and transforms into that structure when, say, the temperature changes," said Stefan Seelecke.

If an electric current flows through a wire made from nickel-titanium, the material heats up, causing it to adopt a different crystal structure with the result that the wire becomes shorter. When the current is switched off, the wire cools down and returns to its original length. The research team creates bundles of these fine shape-memory wires, just as muscle fibers in nature are grouped into fiber bundles.

"The more wires we have, the greater the surface area and the faster we can dissipate heat, which means faster relaxation after contraction," explained Paul Motzki who holds a cross-institutional professorship in smart material systems for innovative production at Saarland University and at ZeMA.

The engineers can control the movement of these artificial muscles so that they contract and relax like real muscle fibers. And because they don't need additional sensors, these drive systems save space and energy. They don't need sensors because the artificial muscles themselves also serve as sensors.

"When the wires change shape, so too does their electrical resistance. We can assign precise resistance values to every deformation, which allows to extract sensory data," said Paul Motzki. The research engineers use these measured values to model and program precise motion sequences.

They can then build components in a modular fashion using these precisely controllable artificial muscles, adapting their designs to the needs of each specific application. For example, if they want to get something to rotate, the engineers make the wires contract and pull on a gear wheel. And as with real muscles, the engineers make use of two muscles working in opposition.

"We deploy our shape-memory wires in agonist and antagonist pairings that work together like flexor and extensor muscles, so that rotation is possible in both directions. When the wire contracts, a lever converts the linear contraction into the corresponding angle of rotation. The shorter the lever, the greater the angle of rotation," explained Paul Motzki. "We have developed a patented rack and pinion mechanism that converts linear into rotary motion, and we'll be exhibiting the prototype at this year's Hannover Messe," he added.

The technology is also scalable, so that larger technical components can also be manufactured. Unlike combustion engines or electric motors and unlike pneumatic or hydraulic systems, the technology being developed in Saarbrücken produces neither noise nor exhaust fumes, and it doesn't need additional equipment such as hoses, valves, pumps or compressors, or rare earths. While at Hannover Messe, the research team will also be looking for partners with whom they can develop their technology for new applications.

More information: Conference: www.hannovermesse.de/en/

Provided by Saarland University