Researchers publish perspective on silicon-based microparticle anodes for lithium-ion batteries

Silicon is one of the most promising anode materials for high-energy lithium-ion batteries. However, silicon-based anodes are not being widely used yet because of a series of challenges that must be solved before silicon can be commercially applied in lithium-ion batteries.

A research team from Huazhong University of Science and Technology has published a review perspective paper summarizing the challenges, outlining the current strategies for engineering silicon-based anodes, and looking to the future prospects for this promising anode material.

Their review perspective is published in the journal Nano Research Energy.

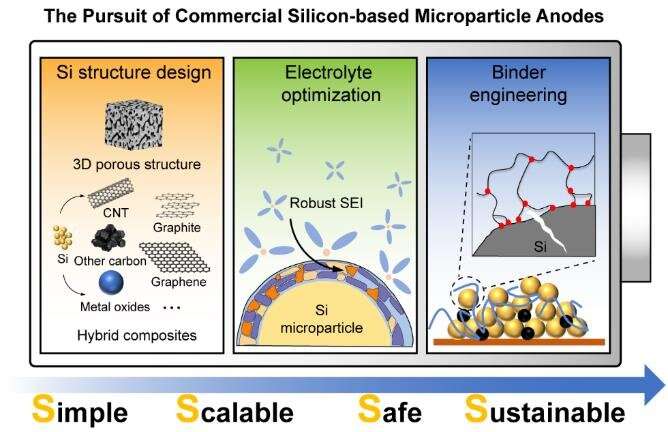

"In this review, we aim to offer some valuable guidelines for the practical application of microscale silicon-based anodes by summarizing the development of silicon-based electrodes fabricated by commercial silicon microparticles from the perspective of industrialization, such as raw materials, preparation process, yield, and environmental friendliness," said Xianluo Hu, a professor in the School of Materials Science and Engineering at Huazhong University of Science and Technology.

While silicon holds strong potential as an anode candidate for next-generation lithium-ion batteries, there are several challenges to be overcome. First, the team notes that nanotechnology, which enables electrode structural stability and long-term cycling, fails to meet the requirements of industrial applications. This is because of its low tap density, significant side reaction, low volumetric capacity, and complex production process with low yields.

Second, the team notes that even though the design of microscale silicon-based anodes has remarkably improved the overall performance of the electrode, the production processes still involve elaborate fabrication steps. These complex steps result in higher energy consumption, environmental pollution, and low yields.

In addition, the team notes that many microscale silicon materials still use nanoparticles as raw materials. These nanoparticles are not practical for large-scale production. So scientists continue to seek simple and eco-friendly ways to achieve the application of low-cost manufacturing silicon-based materials in lithium-ion batteries.

As they consider the prospects of future commercialization of silicon-based anodes, they note that keeping the electrode structure integrity to ensure stable cycling performance is of vital importance when using above low-grade silicon-based materials as the silicon sources. While the combination of porous silicon microparticles and hybrid composites has been studied extensively, not as much study has been done related to failure mechanism analysis of designed micro-sized silicon.

The team notes that binder materials, that hold together the active material particles within the battery's electrode, play a crucial role in keeping structural integrity. They recommend that developing a multifunctional polymer binder with self-healing and conducting properties would help to improve the mechanical strength of the electrodes and to build an extended conductive network. With their high structural advantages, naturally derived polymers should have better success in this role.

"Silicon holds great potential as an anode material for high-energy-density lithium-ion batteries. Constructing highly stable silicon microparticle electrodes from the perspective of simple, scalable, safe, and sustainable technology is challenging and significant," said Hu.

Looking ahead, the team notes that the failure mechanism analysis of designed micro-sized silicon is still lacking based on multi-scale and multi-physical fields. Scientists need to develop in-situ analysis techniques to clarify the relationship between the design strategy and electrode performance.

For instance, the effect of pore distribution on stress dispersion, the evolution of active particle structures, and the dependence of surface chemistry and electric field distribution on carbon modification require an in-depth understanding. They propose that the development of simple, green, efficient, controllable, and energy-saving synthesis technology is pivotal to meeting the requirements of industrial production.

"We expect to realize the application of low-cost silicon-based materials in full cells through electrode material design, electrolyte optimization, and binder innovation by a simple and eco-friendly path," said Hu.

More information: Qing Liu et al, The pursuit of commercial silicon-based microparticle anodes for advanced lithium-ion batteries: A review, Nano Research Energy (2022). DOI: 10.26599/NRE.2022.9120037